Dry CNC Grinding Or Wet CNC Grinding?

However, due to the high temperature generated during processing, many workers choose to use coolant together for processing. Is wet CNC grinding suitable for all processing?

How to choose what is suitable? It is worth considering and analyzing from the following points:

Dry grinding and Wet grinding

Cost:

Dry CNC grinding usually has lower costs and does not require cooling liquid, avoiding the cost of liquid recovery and processing. √

Wet CNC grinding requires additional equipment and coolant, resulting in higher costs. ×

Operational Flexibility:

Dry CNC grinding can be carried out anytime and anywhere, without being limited by environmental conditions, especially suitable for on-site construction or situations where liquids cannot be used. √

Wet grinding requires additional coolant supply systems and drainage equipment, which increases operating and maintenance costs. ×

Dust Generation:

Dry grinding generates a large amount of dust, which poses potential hazards to the environment and the health of operators. Therefore, it is necessary to equip with dust collection equipment or wear protective gear. ×

Wet CNC grinding liquid suppresses dust, creates a cleaner working environment, and is more friendly to the health of operators. √

Thermal Energy Control:

Dry grinding lacks cooling, and friction can generate high temperatures, which may cause tool overheating or material surface deformation. ×

Wet CNC grinding liquid can remove the heat generated during the processing, effectively preventing deformation, annealing, or surface damage of the workpiece due to high temperature. √

Applicable Materials:

Dry CNC grinding is suitable for materials that are sensitive to chemical liquids or water and do not require coolant contamination, such as precision machinery and molds.

Wet grinding is suitable for materials that are not resistant to high temperatures, have high hardness, and require precision machining.

Environmental Impact:

Dry grinding is prone to generating a large amount of dust, which can cause dust pollution. Therefore, good ventilation equipment or dust collection devices are needed to protect the health of workers. ×

Wet CNC grinding waste liquid may cause environmental pollution and needs to be properly disposed of. √

In summary, wet cnc grinding and dry cnc grinding each have their own advantages and disadvantages, and are suitable for different processing requirements and material characteristics.

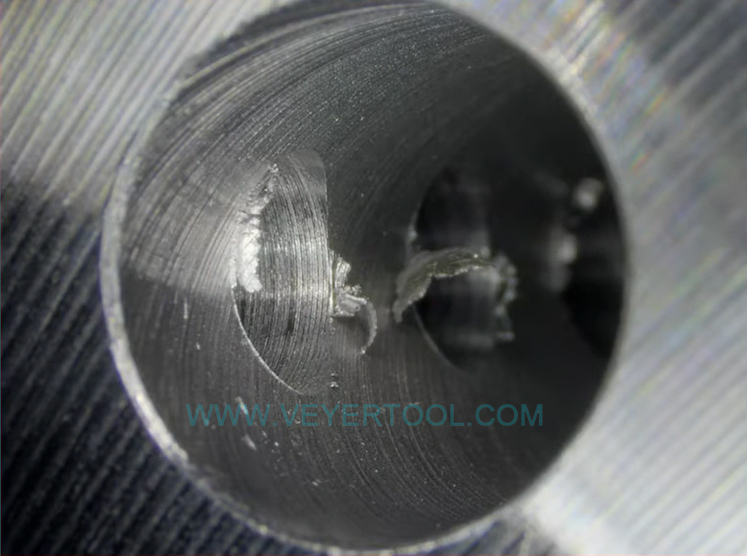

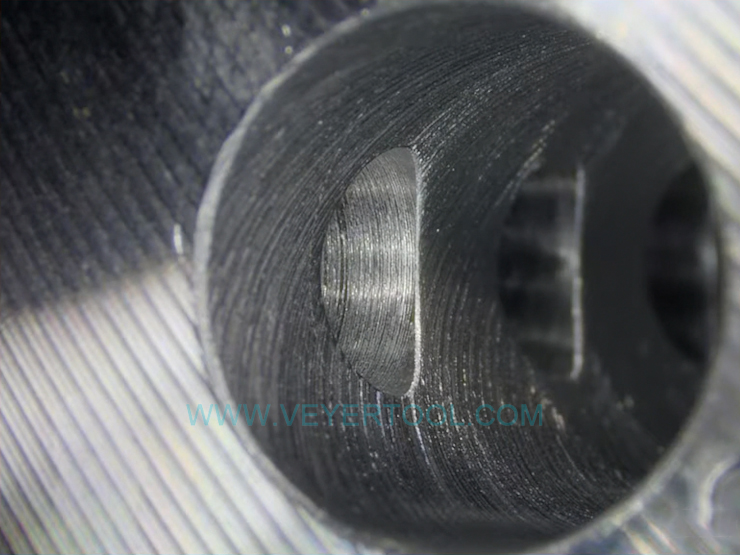

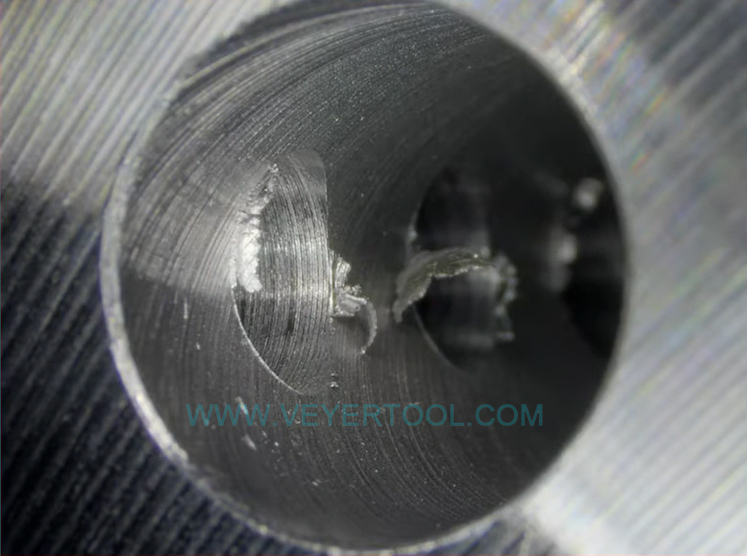

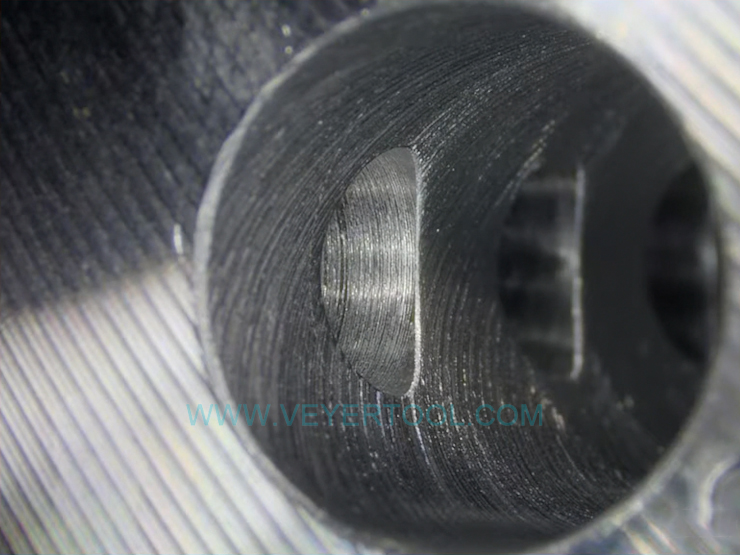

The effect after cnc grinding is shown in the following figure:

Before deburring and After deburring

Dry grinding and wet grinding each have their own advantages and disadvantages, and the choice of method depends on processing requirements, material properties, and operating environment.

Summary:

Dry Grinding

Advantages: Lower cost, no need for coolant; Flexible operation; Suitable for precision machinery and mold processing that cannot be affected by coolant

Disadvantages: prone to generating a large amount of dust, affecting the environment; The high temperature of precision machining friction can easily cause deformation of the workpiece

Wet Grinding

Advantages: Inhibit dust generation and build a green environment; Can effectively cool down and maintain the shape of the workpiece; Suitable for precision machining materials that are not resistant to high temperatures and have high hardness

Disadvantages: High cost, requiring specific equipment and coolant; Further maintenance is required regarding the discharge of waste coolant, etc

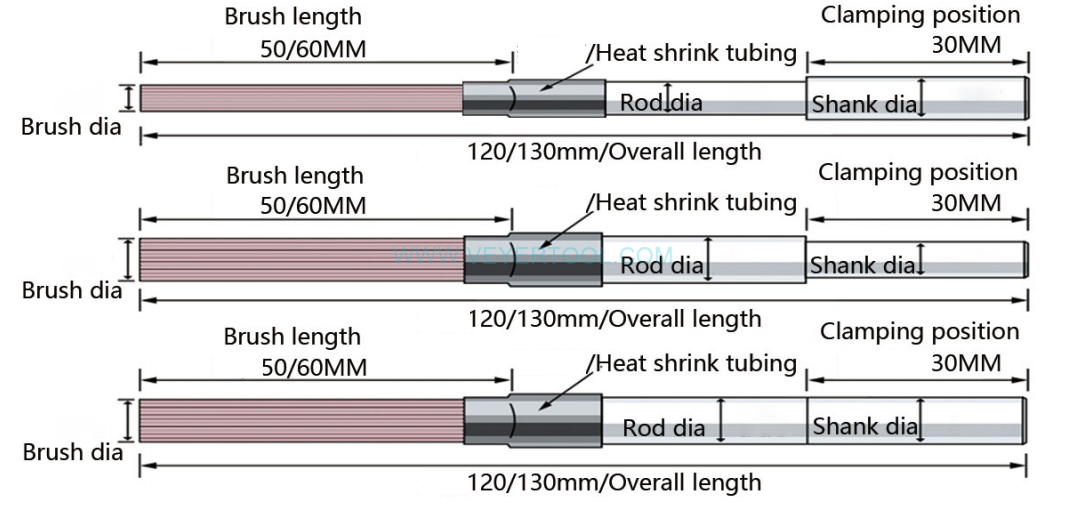

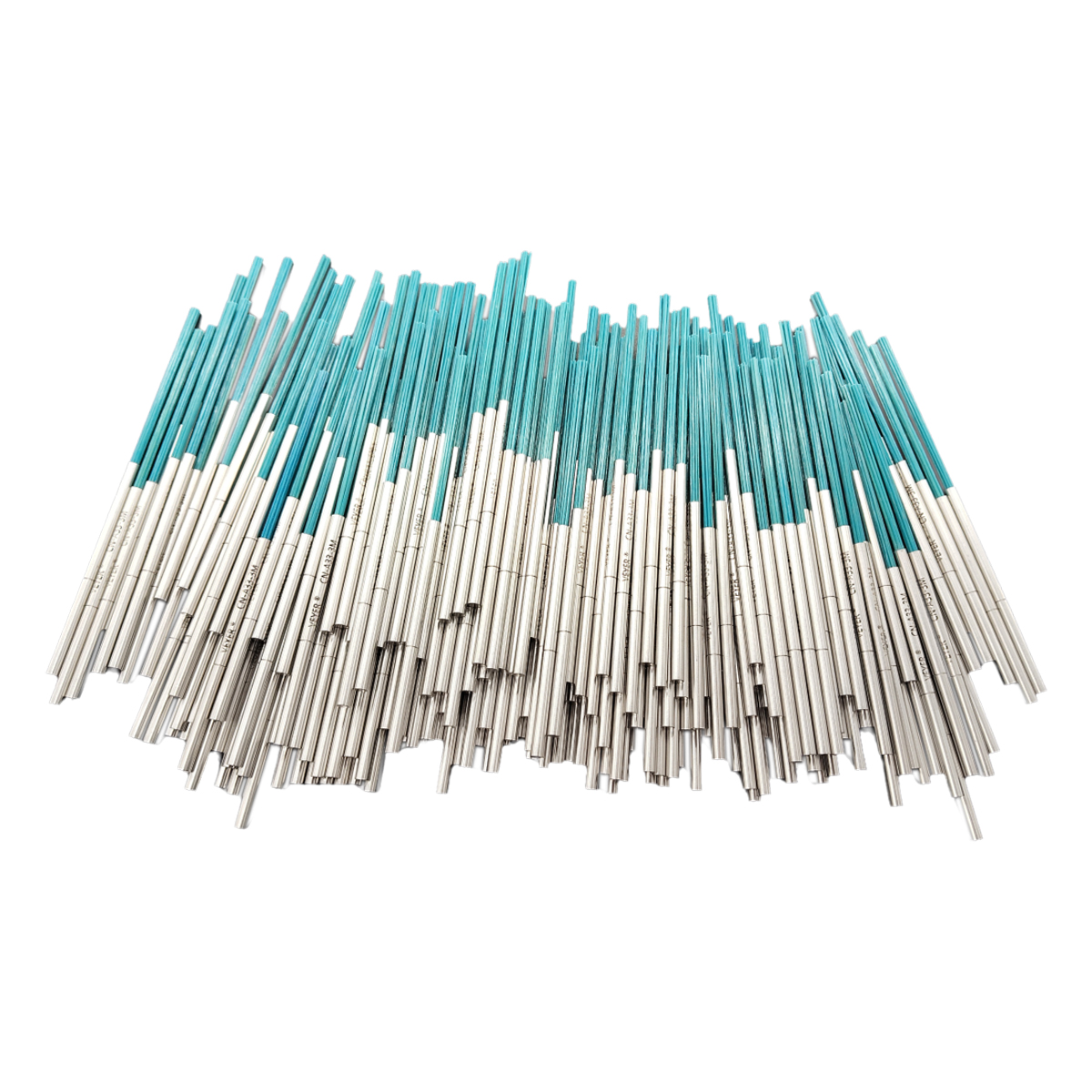

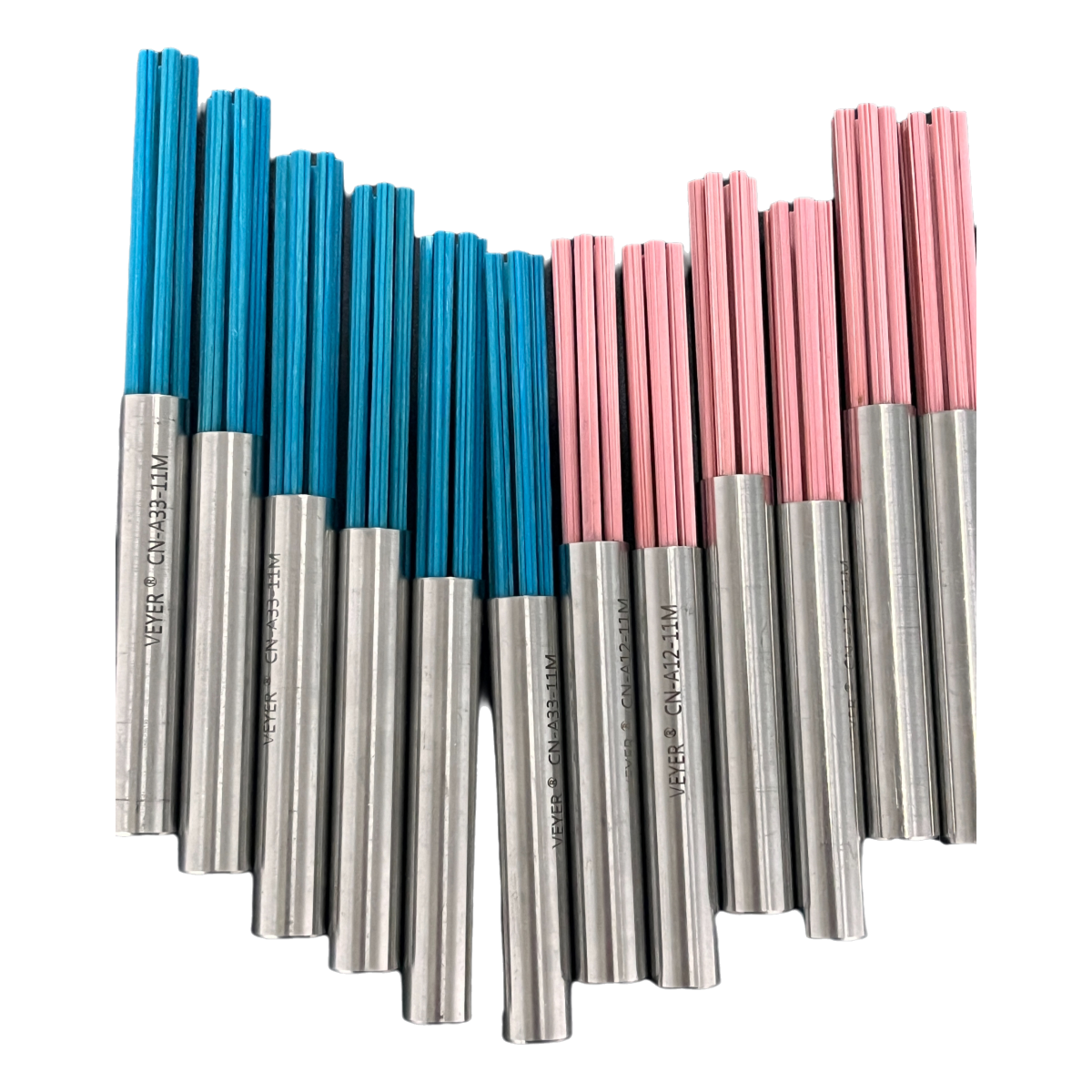

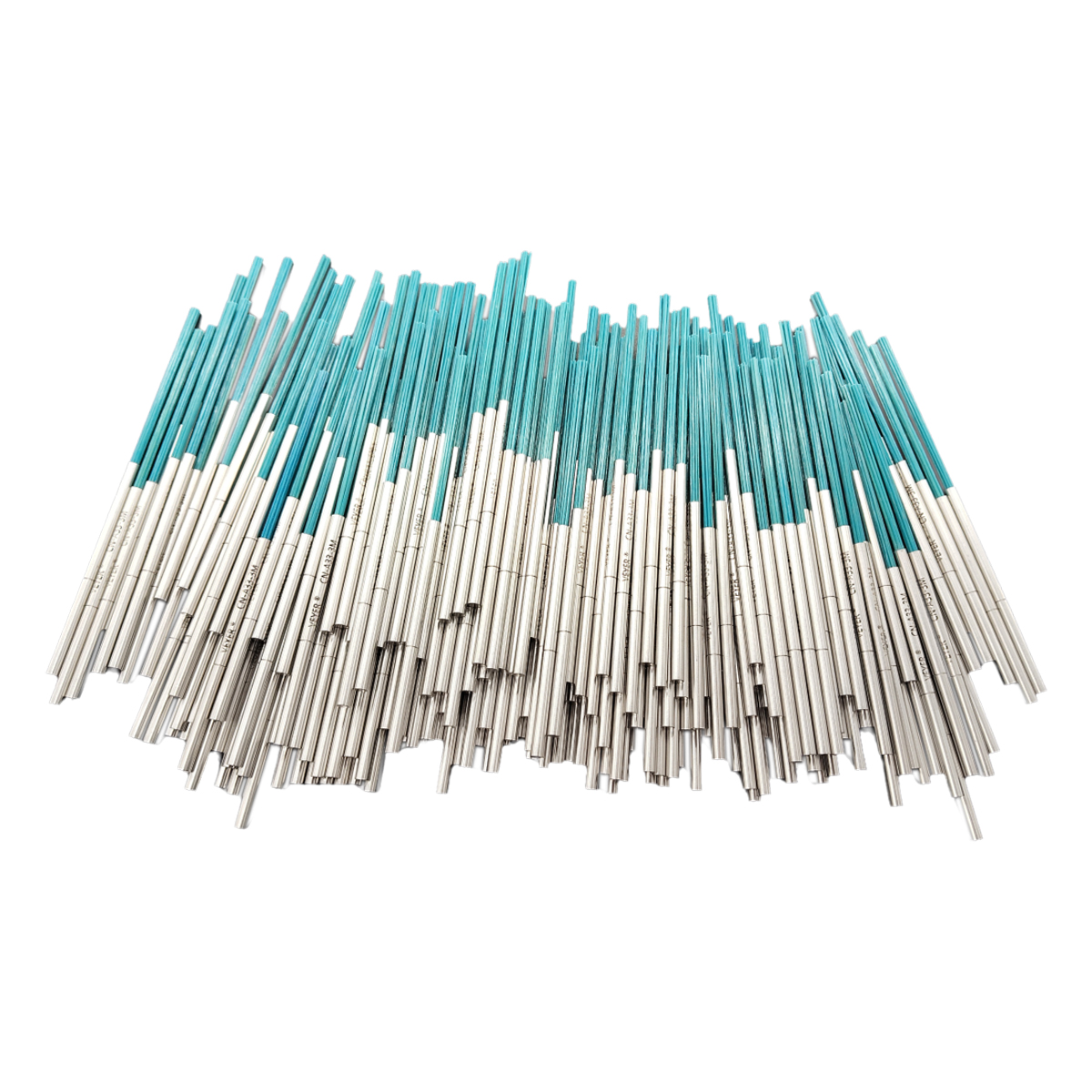

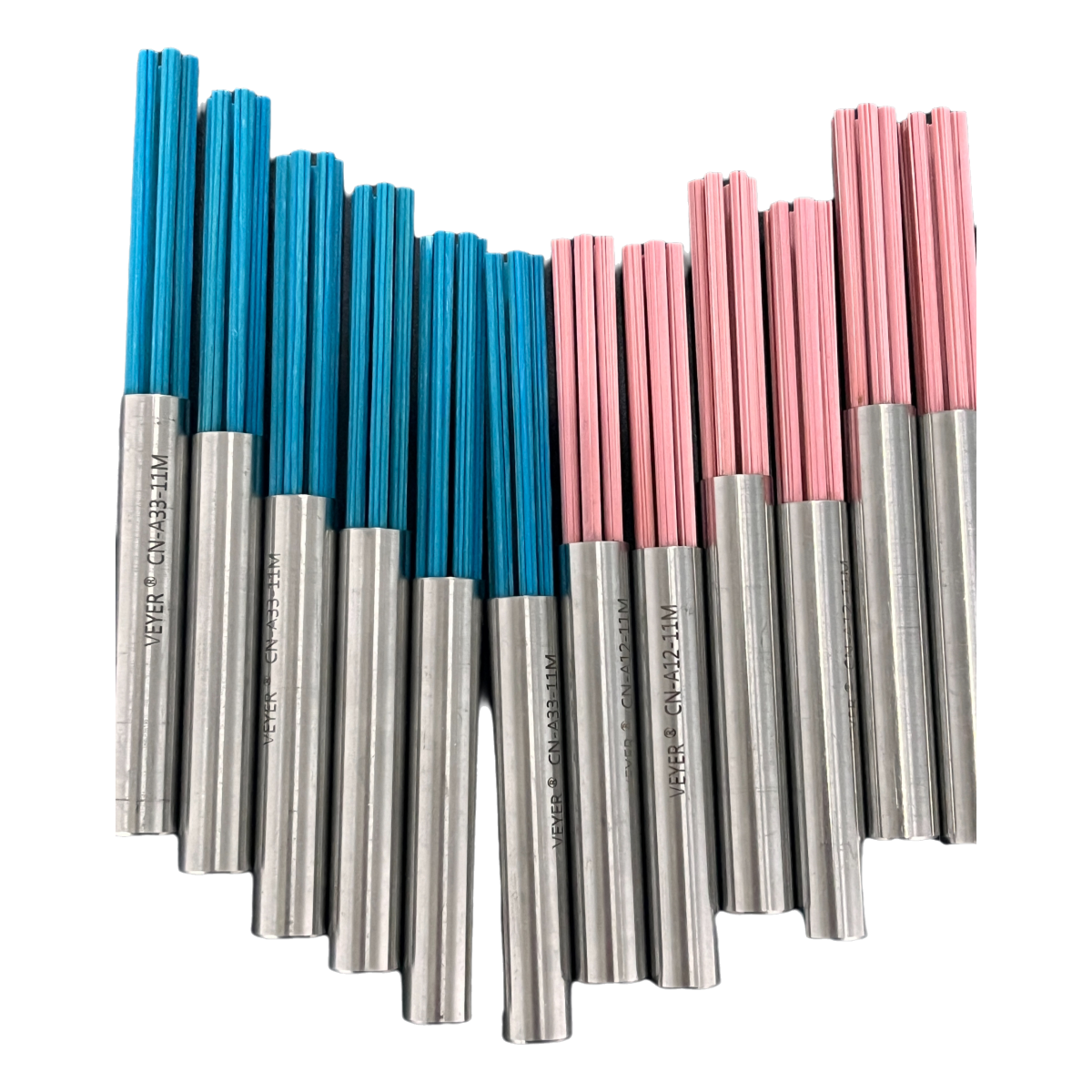

VEYER's ceramic fiber inner hole deburring brushes

The bristles are made of ultra-fine fiber oilstone, and when rotating, centrifugal force is used to give the bristles a strong cnc grinding force at the head. It will not damage the internal shape or size of the hole, making it very suitable for working on CNC and automation equipment, flexible, efficient, and low-cost.

Suitable for deburring, polishing, drawing, removing tool marks, rust removal, descaling, and changing roughness of metal parts' inner and cross holes.

For more deburring tools, kindly contact VEYER directly !

Deburring Polishing Finishing Brushes:

Surface deburring finishing tools: Surface Ceramic Fiber Brush,Extra Large Surface Ceramic Fiber Brush, End Type Ceramic Fiber Brush...//Stainless Steel Wire Brush...

Cross internal holes tools : Internal Cross Holes Ceramic Fiber Brush, Flex Ball Hone,Micro Holes Ceramic Fiber Brush...

Micro mini tools: Micro Holes Ceramic Fiber Brush// Ceramic Deburring Brush

Back or side burrs tools: Flexible Oil Stone Grinding Rod

Threads tools: Side Wheel Brush, Pipe Hole Brush...

Application:

Automated Deburring, Crosshole Deburring & Finishing, Detailed Finishing, Manual Deburring, Surface Deburring & Finishing, Metal cleaning,Mold polishing...

Widely used in CNC Machining Centers, Combined Lathes, Robotics Hand, Special machines,Bench Machine, End Milling Drilling Machine, Full Automatic Deburring Station, Aotumatic Production Line or Some used with Hand Electric Drill...

Industry:

3C Electronic Metal Parts, Mechanical Accessories, Precision Hardware Parts, Automobile Powertrain Motor Cylinders Head, Aerospace,New Energy, Medical Healthy, Robotics...