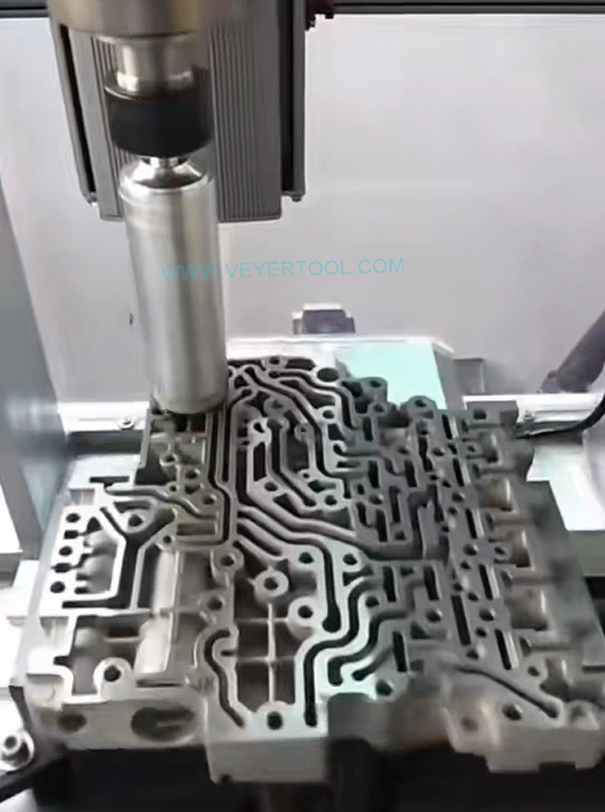

Ceramic fiber surface brush clamped on CNC for deburring

Ceramic fiber brush deburring is an important tool in modern industrial manufacturing. When clamped on CNC or other spindles for deburring operations, it not only has high efficiency but also ensures processing quality. And it is widely used in fields such as mechanical processing, metal processing, aerospace, automotive manufacturing, medical equipment, precision instrument manufacturing, etc.

Ceramic fibers have better wear resistance than many other materials, which means that ceramic fiber brushes have a longer service life.

The grinding brush can maintain a straight shape, and even after repeated use, it will not scatter like a toothbrush. It is suitable for machining deburring and polishing on large-scale production lines.

Ceramic fiber brushes can penetrate into the tiny gaps on the surface of the workpiece, accurately remove burrs, and protect the remaining surfaces of the workpiece from damage.

Ceramic fiber brushes reduce processing time by reducing the number of passes, while improving polishing quality by minimizing overlap, which can achieve good surface roughness in a short period of time and greatly shorten grinding time.

Method of manually scraping burrs with a scraper

Scraper deburring is a traditional deburring tool commonly used to remove burrs from the edges of workpieces after metal processing. Use files (including manual and pneumatic files), sandpaper, sanding machines, grinding heads, etc. as auxiliary tools.

The use of the scraper is relatively simple, and operators only need to master basic usage skills to get started, suitable for production environments of various scales.

2.Low Tool Cost:

Compared with other deburring tools such as machining deburring, the initial investment and maintenance cost of the scraper is lower.

The scraper has a small volume and light weight, making it easy to carry and store, and suitable for on-site operations.

The disadvantages of this tools are high labor costs, low efficiency, and difficulty in removing complex cross holes. Suitable for small-scale and precise deburring operations.

How would you choose between these two deburring tools? Both deburring tools have their own advantages. Choose the most suitable deburring tool based on your actual situation! But I still highly recommend VEYER BRUSH ceramic fiber surface brush, which has a higher overall cost-effectiveness, higher efficiency, and better results!

For more deburring tools, kindly contact VEYER BRUSH directly !

Deburring Polishing Finishing Brushes:

Surface deburring finishing tools: Surface Ceramic Fiber Brush,Extra Large Surface Ceramic Fiber Brush, End Type Ceramic Fiber Brush...//Stainless Steel Wire Brush...

Cross internal holes tools : Internal Cross Holes Ceramic Fiber Brush, Flex Ball Hone,Micro Holes Ceramic Fiber Brush...

Micro mini tools: Micro Holes Ceramic Fiber Brush// Ceramic Deburring Brush

Back or side burrs tools: Flexible Oil Stone Grinding Rod

Threads tools: Side Wheel Brush, Pipe Hole Brush...

Application:

Automated Deburring, Crosshole Deburring & Finishing, Detailed Finishing, Manual Deburring, Surface Deburring & Finishing, Metal cleaning,Mold polishing...

Widely used in CNC Machining Centers, Combined Lathes, Robotics Hand, Special machines,Bench Machine, End Milling Drilling Machine, Full Automatic Deburring Station, Aotumatic Production Line or Some used with Hand Electric Drill...

Industry:

3C Electronic Metal Parts, Mechanical Accessories, Precision Hardware Parts, Automobile Powertrain Motor Cylinders Head, Aerospace,New Energy, Medical Healthy, Robotics...

Contact: Annie Fu

WhatsApp: +8618819762043

Email: annie@veyertool.com

Add: Room2121,Office Building 5A,Mingfa Commercial Plaza,Changsha City,CHINA.