There are many reasons that can cause the formation of stainless steel knife marks. You can correspond to which process your stainless steel part knife marks are generated in!

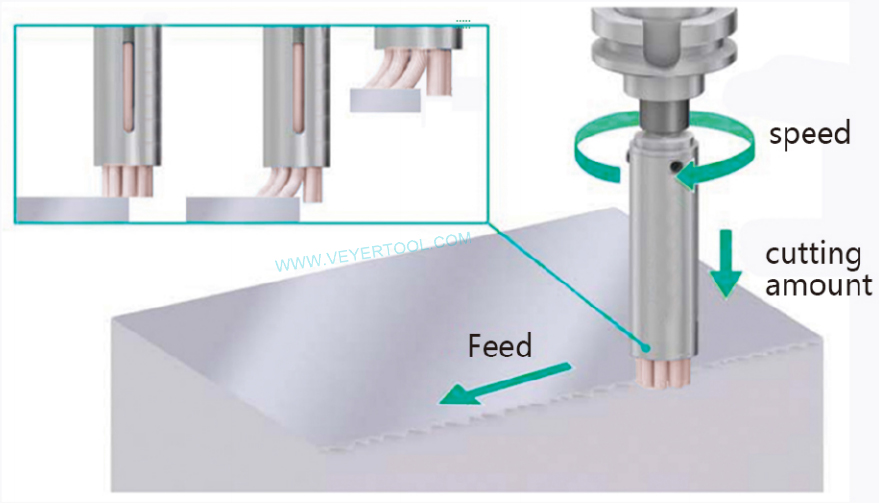

1.Excessive Cutting Speed: This makes it difficult for the material to lose cutting heat in a timely manner during the cutting process, resulting in local overheating and the formation of tool lines.

2.Uneven Feed Rate: Uneven feed rate can cause uneven distribution of cutting force, resulting in tool lines on the surface of the workpiece.

3.Tool Wear: Tool wear can lead to an increase in cutting force, affecting the stability of the cutting process and resulting in tool lines.

4.Poor Lubrication: Lack of sufficient lubricant or uneven lubrication can lead to increased friction between the material and the CNC cutting tools during cutting, resulting in tool lines.

5.Uneven Hardness And Properties Of Materials: The uneven distribution of material hardness and properties can lead to changes in cutting force during the cutting process, resulting in tool lines.

There are actually many methods to remove knife marks, but it is difficult to choose the most cost-effective method.

Simultaneously considering Efficiency, Durability, Versatility, Environmental Friendliness, and Low Cost.

To meet the above requirements, ceramic fiber deburring brush are a good choice, providing an efficient, durable, and stable solution for removing blade lines from stainless steel materials, while also reducing production costs and improving production efficiency.

Surface ceramic fiber brush - blue (suitable for metals such as stainless steel and iron)

This ceramic fiber surface deburring brush is very suitable for deburring, removing knife marks, surface polishing, drawing, rust remover, removing oxide skin, changing roughness, etc. on the surface of metal parts and groove bottoms. Simply equip the product with CNC and automation equipment to work flexibly, efficiently, and at low cost.

Our products are widely used. If you have any problems with metal parts processing, you can contact us directly. Our products can help you solve the problems you are troubled by.

Are you already eager to make a purchase? You can directly search for "WWW.VEYERTOOL.COM"

Contact: Annie Fu

WhatsApp: +8618819762043

Email: annie@veyertool.com

Add: Room2121,Office Building 5A,Mingfa Commercial Plaza,Changsha City,CHINA.