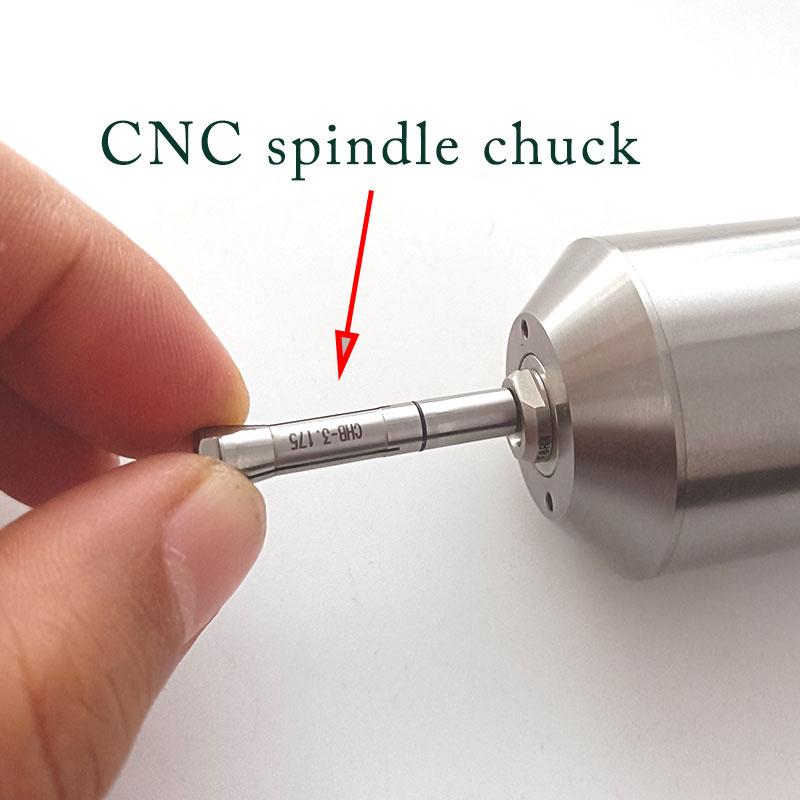

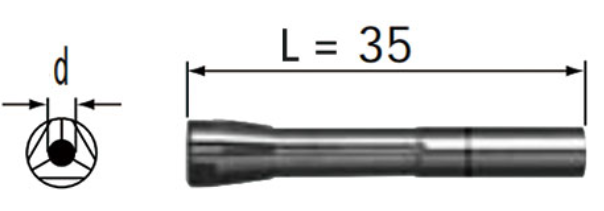

⭕Features: 1--High-precision clamping: Effectively reduces tool deflection and vibration. 2--Flexibility and adaptability: A variety of specifications and models. 3--Strong clamping force: The tool remains stable during high-speed rotation and load changes. 4--High durability: Made of high-quality alloy steel or special materials. 5--Customization options: Can be customized according to customers' specific application requirements.

Q: When will you arrange the production ?

A: Production will be usually arranged immediately after receiving your payment.

Delivery usually about 20-45 days.

Q: Which payment ways I can choose?

A: Usually, T/T, Paypal...If I want to use other ways, kindly share VEYER.

Q: What logistics forwarder do you usually work with?

A: We work with DHL,UPS, FEDEX...& COSCO,MSK,EVERGREEN...

Q: Do you have a MOQ?

A:Our MOQ are usually 100 pcs. (Small QTY are negotiated.) (samples support)

Contact: Annie Fu

WhatsApp: +8618819762043

Email: annie@veyertool.com

Add: Room2121,Office Building 5A,Mingfa Commercial Plaza,Changsha City,CHINA.