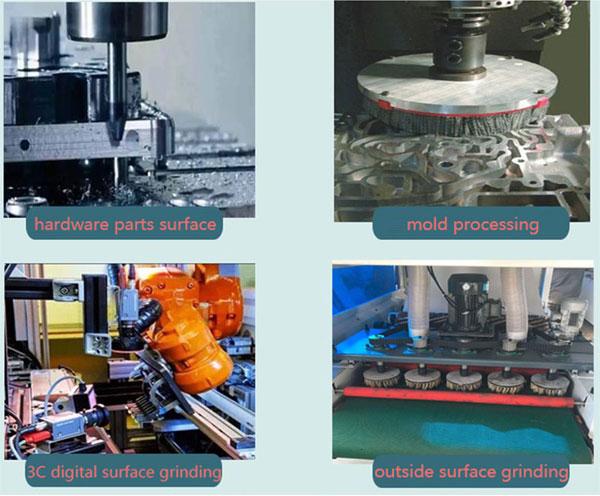

⭕Features: 1--Shiny Smooth Effect After deburring polishing, very shiny smooth, can reach Ra 0.1. 2--Fast efficient VEYER brushes can remove burrs for surface quickly. 3--New no damage grinding The treated surface is completely free of any scratches, tears or folded metal. 4--Wide application Suitable for the surface of metal parts and the bottom surface of the groove.

Deburring of aluminum parts

Case time: September 25, 2023

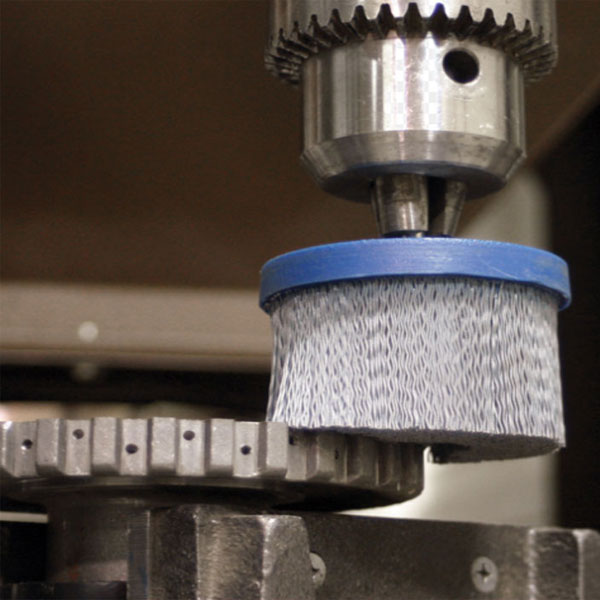

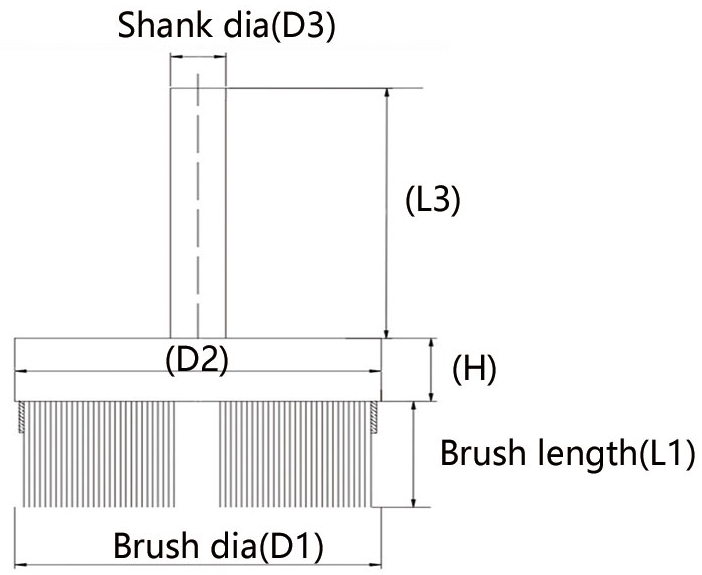

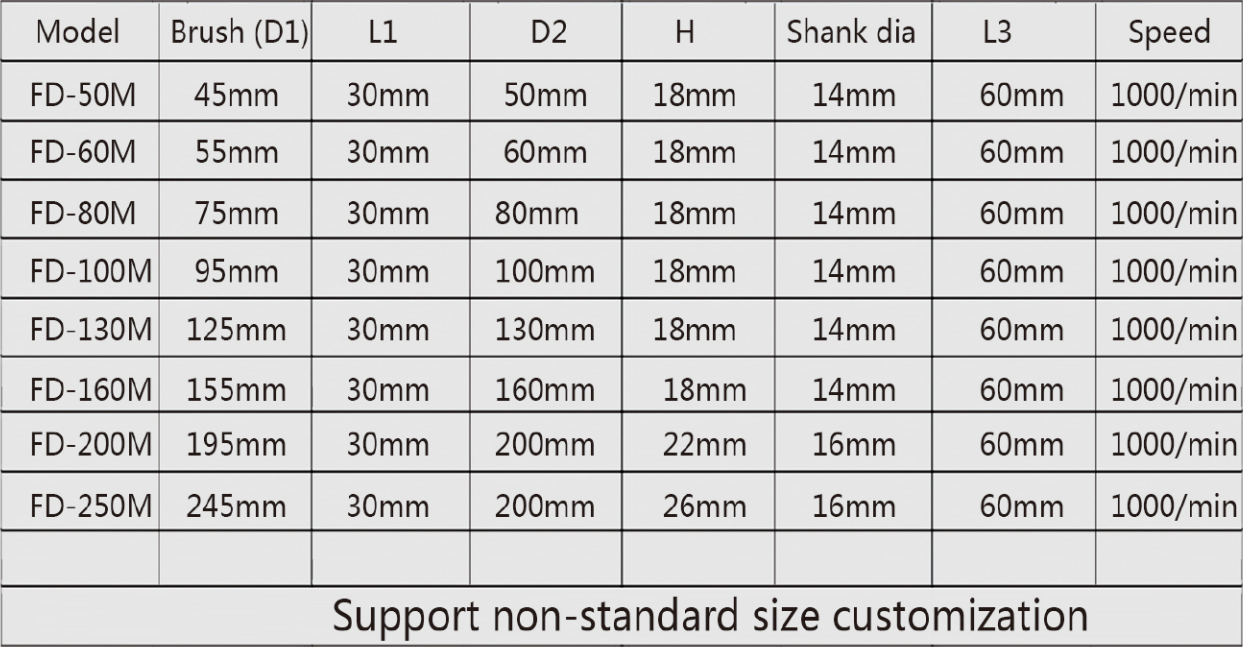

Tool Used: VEYER round dics Deburring brush

Type: FD-100M

RPM: 1000min

Case outline: The client is a local China Taiwan processing plant that usually processes a lot of aluminum products. There are many burrs on the metal surface that need to be cleaned,the customer bought VEYER's deburring brush. After grinding on CNC lathe, the aluminum alloy surface is very smooth, without any burrs remaining.

The tools previously used by the customer: Traditional manual sandpaper grinding( The customer lamented which wasted a lot of manpower and time.)

Before deburring:There are many small burrs on the metal surface

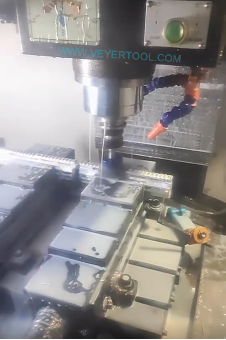

Grinding on CNC:As the lathe spindle rotates, the burrs on the aluminum alloy parts are quickly and thoroughly removed.

After deburring:the originally rough and uneven surface becomes extremely smooth without any burrs remaining.

Now, automation is adopted to quickly solve the problem of deburring and polishing. The customer's aluminum product surface finishing treatment technology has been improved in consistency, and production efficiency has also been improved. The quality of aluminum products has also been recognized and praised by more manufacturing industries.Customers also reported that it is great for polishing , and better than the German deburring tools, saving more costs and manpower.

The VEYER CNC deburring Brush are made of High quality Silicon carbide wire filament.When grinding,the uniformly sized abrasive bristles have a very good deburring force.It will not damage the surface shape and size.It is very suitable for equipping on CNC,automatic machines,mini bench machine.....to work,flexible,efficient and low-cost.The functions are suitable for flank deburring, cutter patterns traces/ cut marks removal, polishing, wire drawing and rust removal, descaling and improve roughness on the surface and the bottom surface of the groove of metal parts...

Q: Which payment ways I can choose?

A: Usually, T/T, Paypal...If I want to use other ways, kindly share VEYER.

Q: What logistics forwarder do you usually work with?

A: We work with DHL,UPS, FEDEX...& COSCO,MSK,EVERGREEN...

Q: Do you have a MOQ?

A:Our MOQ are usually 100 pcs. (Small QTY are negotiated.) (samples support)

Contact: Annie Fu

WhatsApp: +8618819762043

Email: annie@veyertool.com

Add: Room2121,Office Building 5A,Mingfa Commercial Plaza,Changsha City,CHINA.