⭕Features: 1--Super Effective Consistent Precision Grinding Force VEYER developed great Ultra-fine ceramic fiber filaments abrasives. With efficient grinding force. 2--Without Damage when Deburring and Polishing For VEYER excellent cutting fiber, leaving no scratches on the surface. 3--Does not Deform Easy More durable than other abrasive nylon brushes

Tool Used: VEYER surface Deburring Tools Ceramic Fiber brush

Type: CN-CB15HS

RPM: 5000min

Process Time: 5 sec

Material: Stainless steel

·Unlike traditional brushes, VEYER deburring surface polishing brushes use advanced ceramic fiber technology. Our bristles have the characteristics of high temperature resistance, strong stability, and good processing performance. When rotating, centrifugal force is used to give the brush head a strong grinding force. Fine machining of metal materials through contact grinding surface friction.

·Our ceramic fiber bristles are designed to quickly remove burrs while maintaining a smooth material surface and providing a polishing effect. It is usually used for precision machining and surface processing. Choose our ceramic fiber surface polishing brush, which can be automatic or manual, making your deburring and polishing process more efficient.

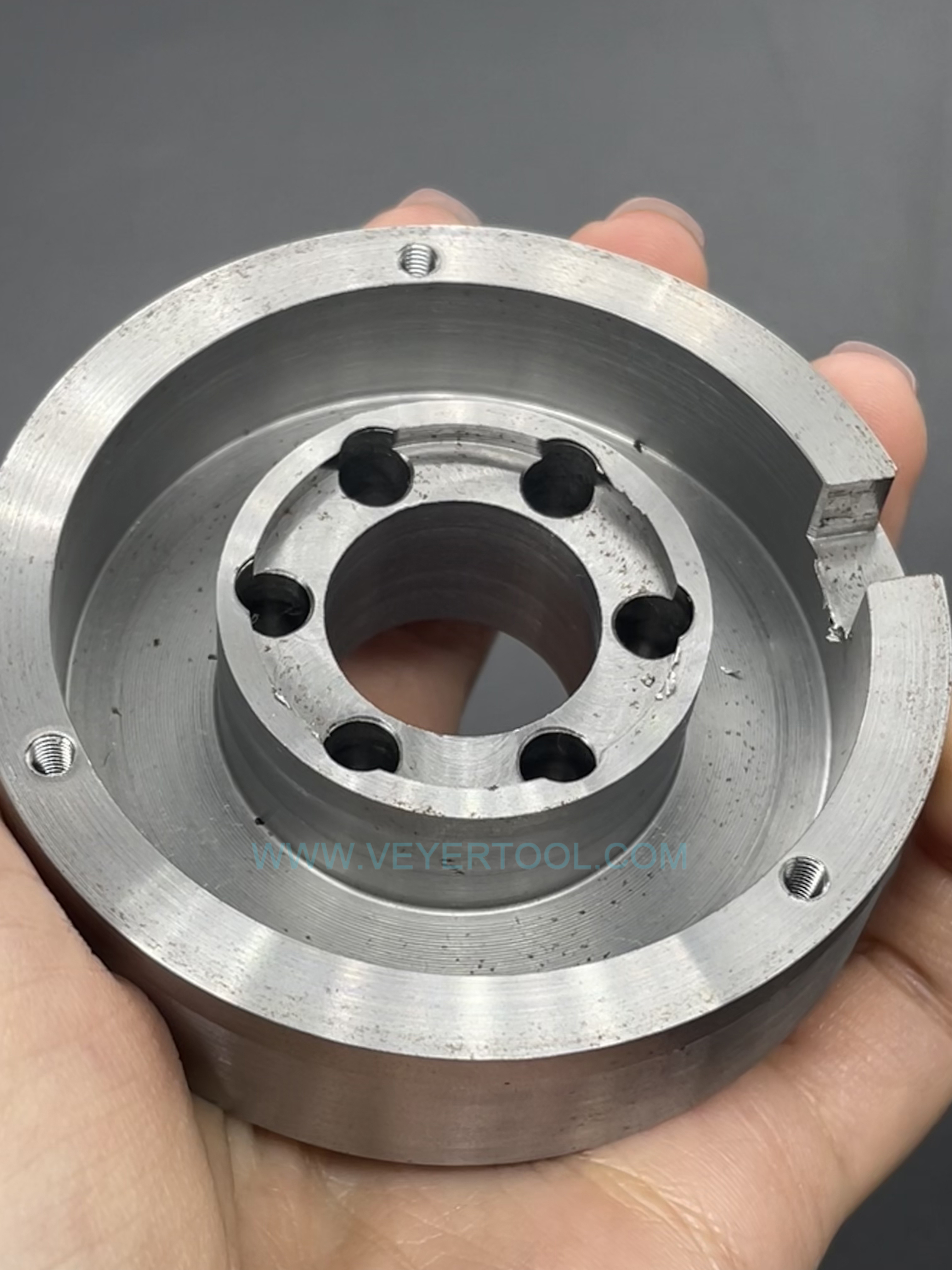

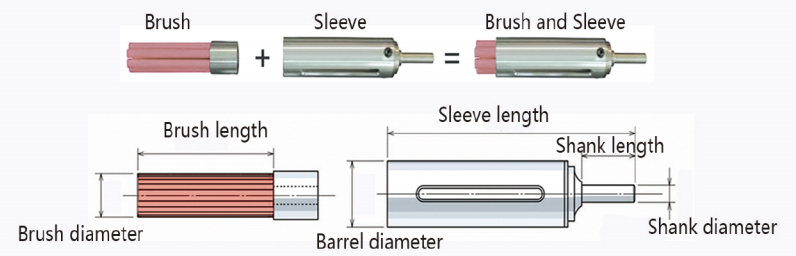

·High quality and uniform ceramic fiber bristles, finely ground, without damage to the workpiece, especially suitable for burrs on the surface of parts and groove bottoms. It is composed of a brush and a sleeve, and the handle of the sleeve is very suitable for equipping on CNC to achieve automated work.

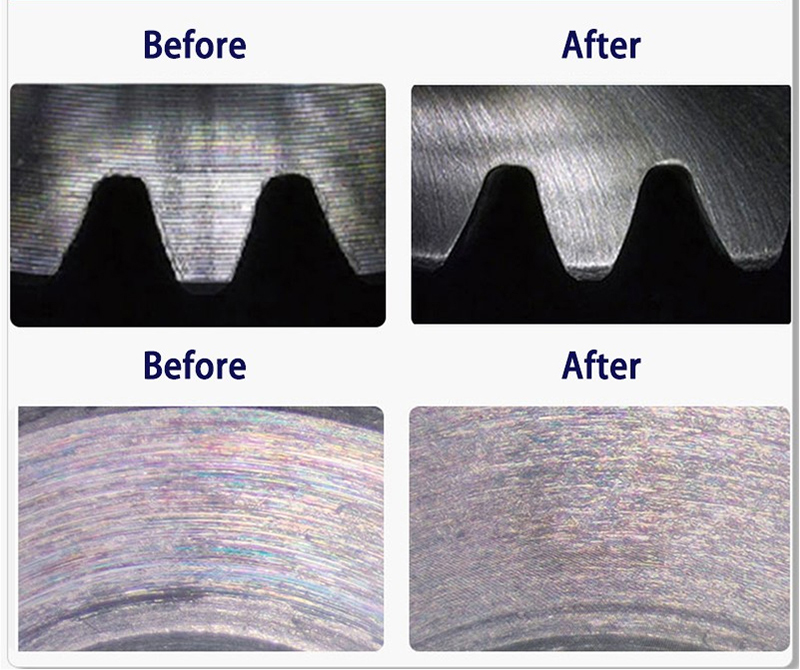

VEYER ceramic fiber CNC deburring brushes are suitable for plane deburring, cutter patterns traces/ cut marks removal, polishing, wire drawing and rust removal, descaling and improve roughness on the surface of metal parts and the bottom surface of the groove...The brushes are very nice deburring tools, so right for you.

It is very suitable for CNC machining center, milling drilling lathes, automatic machines, robot hand...The functions are suitable for plane deburring, cutter patterns traces/ cut marks removal, polishing, wire drawing and rust removal, descaling and improve roughness on the surface of metal parts and the bottom surface of the groove..., also great brush for cylinders valve surface polishing and deburring.

1--Super Effective Consistent Precision Grinding Force

VEYER developed great Ultra-fine ceramic fiber filaments abrasives. Thousands of cutting edges are formed at the end of each individual fiber, providing excellent cutting ability, with efficient grinding force.

More durable than other abrasive nylon brushes

2--Without Damage when Deburring and Polishing

After face of metal deburring or surface polishing, the impact on the metal surface is almost negligible, almost same as before. For VEYER excellent cutting fiber, leaving no scratches on the surface.

3--Does not Deform Easy

More durable than other abrasive nylon brushes

VEYER surface polishing ceramic fiber CNC deburring brushes are great for CNC Robotics deburring and polishing, without damage for metal parts when grinding. The metal finishing effects are great, reaching very smooth and shiny surface. Commonly used in aluminum alloys,copper, magnesium alloy, stainless steel, iron with small burrs like below 0.2mm.

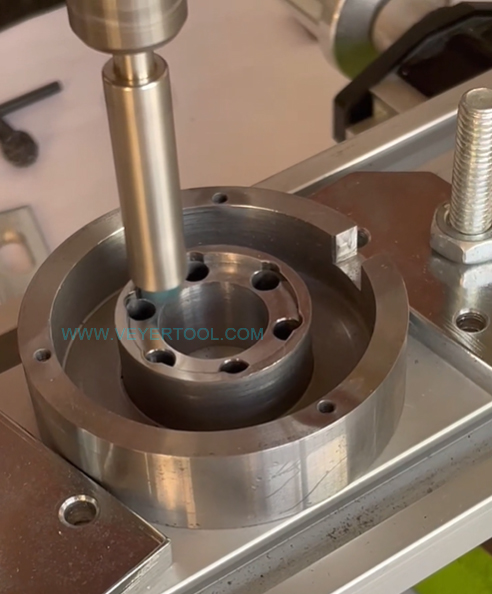

1. Put the brush into the sleeve and tighten it, and the sleeve shank part is clamped on the spindle of the machine tool;

2. The machine tool is programmed to set the speed, feed, tool volume, etc.;

3. Make the brush head contact the grinding surface, and walk the stroke and reciprocate grinding on the surface.

Product name: surface ceramic fiber brush

model: CN-CB

Bristles: ceramic fiber filaments ➕ Sleeve: stainless steel

Color:

pink(for metals such as aluminum alloy and copper)

Blue(for metals such as stainless steel and iron)

A---Sizes of VEYER micro cross holes cnc polishing brush from diameter 1mm, 1.5mm, 2mm,2.5mm...3mm...

B---On machining parameters: recommend changeable speed is about 7 000 rpm, feed is about from 200mm to 1000 mm.

C---Great for softer metal material, pink CB31R-S series cnc deburring brushes usually for aluminum alloy, copper...

With more strong grinding power and nice cutting action, so blue CB31B-S series brushes usually for magnesium alloy,stainless steel, iron, die casting...harder metal type, after drilling or end milling

Q: When will you arrange the production ?

A: Production will be usually arranged immediately after receiving your payment.

Delivery usually about 20-45 days.

Contact: Annie Fu

WhatsApp: +8618819762043

Email: annie@veyertool.com

Add: Room2121,Office Building 5A,Mingfa Commercial Plaza,Changsha City,CHINA.