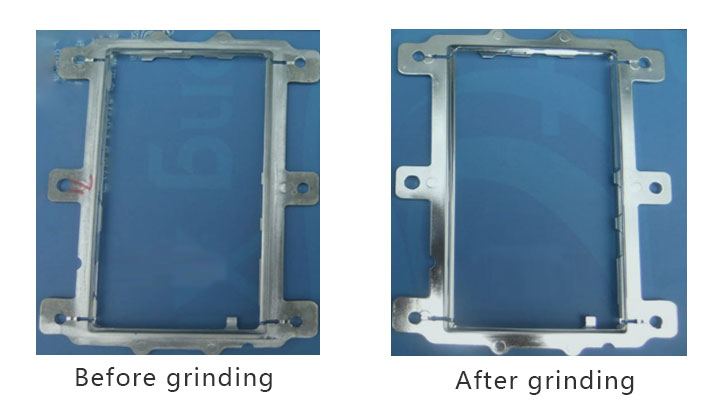

Deburring of aluminum surface

| Processing background | After the aluminum parts 6061 are rough-machined and formed by CNC machine tools, the surface is rough, and a large number of burrs can be seen to be treated with the naked eye. | |||||||

| Purpose of processing | Remove burrs, reduce surface roughness, and require roughness RA0.8 or less. | |||||||

| Workpiece material | Aluminum parts 6061 | |||||||

| Use a brush | VEYER Ceramic fiber surface brush CN-06MS | |||||||

| Processing conditions | Automatic grinding of CNC machine tools | |||||||

| Machining parameters | The speed is S=5000r/min, the amount of cutting = 0.5mm, and the feed is F=1000mm/min | |||||||

| Processing time | Go back and forth twice on the square surface, about 15 seconds | |||||||

| Processing effect | Perfectly remove about 0.2mm burr, smooth surface after grinding, and the roughness of the instrument test reaches RA0.6 | |||||||

| Service life | In the actual use of the customer, one brush can grind more than 3,000 workpieces | |||||||

Contact: Annie Fu

WhatsApp: +8618819762043

Email: annie@veyertool.com

Add: Room2121,Office Building 5A,Mingfa Commercial Plaza,Changsha City,CHINA.