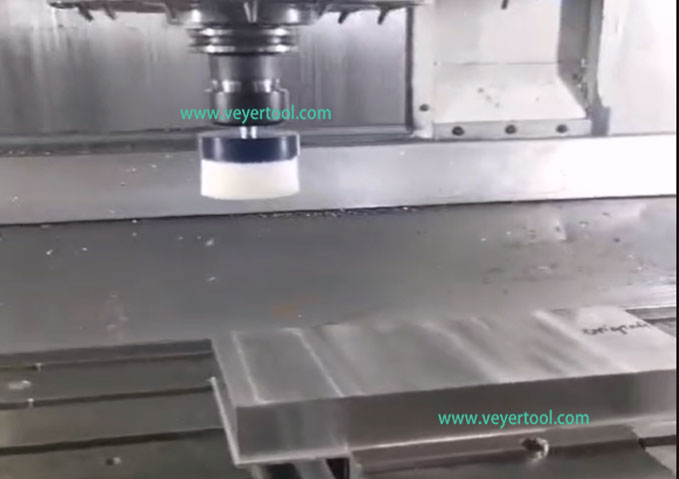

CNC machining aluminum workpiece to remove surface knife lines

Aluminum alloy materials are often widely used in automobiles,

3C electronics, aerospace and other fields.However, in the process of processing,

the surface of aluminum alloy is prone to knife lines, scratches, etc.,

which affects the appearance and performance.

Here we introduce a very practical method for removing knife marks

and scratches from aluminum alloys.

1. Choose the right abrasive tools to achieve the purpose of fast

and automatic grinding and polishing, such as: VEYER brand ceramic wire brush

2, the ceramic wire brush is clamped on the CNC machine tool, so that after the tool is processed,

Automatic shaft change, seamless connection with brush grinding aluminum alloy surface,

to achieve automatic grinding, saving time and cost.

3. Clean the surface of the aluminum alloy, adjust the CNC parameters,

according to the size of the brush used,

Adjust the speed of about 2000-5000, feed 500-2000,

and the amount of cutting 0.5-1.0mm.

The brush is evenly ground on the surface of the aluminum alloy

to achieve the effect of removing the knife lines and polishing the surface.

Summary: This method of removing knife lines on the surface of aluminum alloy,

in practical applications,Different abrasive brush filaments can be selected according

to the hardness of aluminum alloy material.

Brush filaments generally include silicon carbide filament, ceramic filament,

diamond filament, ceramic fiber filament, etc.

The machining process needs to adjust the processing parameters

to avoid surface damage due to over-processing or the brush is not durable.

For details, please refer to the official website www.veyertool.com VEYER.

Contact: Annie Fu

WhatsApp: +8618819762043

Email: annie@veyertool.com

Add: Room2121,Office Building 5A,Mingfa Commercial Plaza,Changsha City,CHINA.