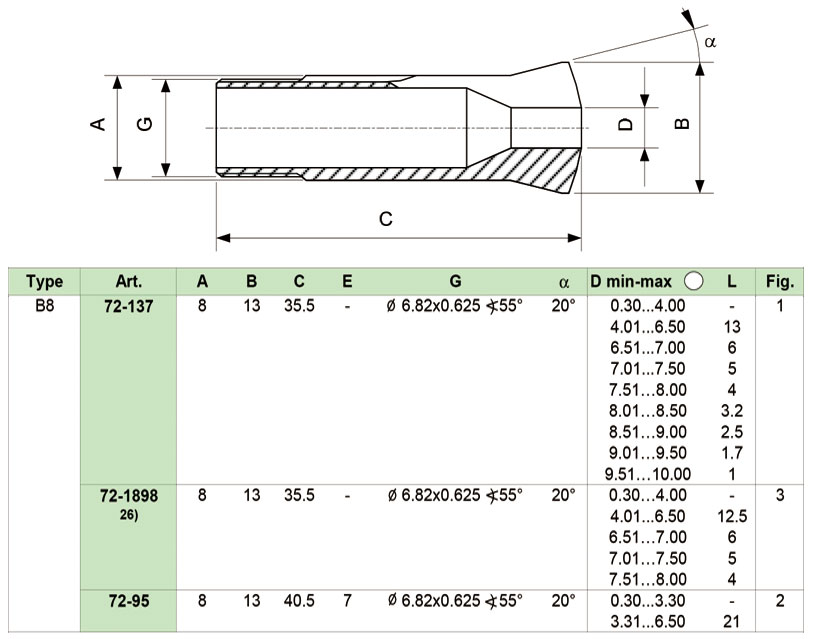

"B" shaped chuck, clamped from behind using a chuck wrench. The outer diameter of the thread is less than the diameter of the shaft (guide diameter). The "B" chuck is generally used in tool manufacturers' lathes and precision machine tools, and can also be used as a material chuck on production machines. When used on a tool manufacturer's lathe, the chuck has a small opening and needs to ensure a good concentricity.

Mini high-precision chucks are mainly used for high-precision clamping and positioning of small or precision tools, grinding heads, drill bits, etc. in precision machining environments to ensure the stability and accuracy of tools under high-speed operation. The following are some common functions and features. Including but not limited to CHK CHB CHA chucks produced by the Chinese VEYER brand and other types of mini precision chucks such as grinder chucks:

1. High-precision clamping:

Extremely high clamping accuracy and repeatable positioning accuracy, meets micron-level processing requirements, effectively reduces tool deflection and vibration, and improves the processing quality of workpieces.

2. Compact and lightweight:

Due to its small size and light weight, the mini high-precision chuck is particularly suitable for precision processing situations with limited space, such as micro-component processing, precision mold manufacturing, medical device manufacturing, and fine grinding machines used in the semiconductor industry.

3. Flexibility and adaptability:

A variety of specifications and models 3mm 3.175mm or 1/8" 4mm... are available, which can adapt to tools or grinding heads of different diameter ranges. The quick-change design also makes tool replacement more convenient and efficient. Suitable for Lathe ATC spindles

4. Strong clamping force:

Although small in size, it is well designed to provide sufficient clamping force while maintaining precision clamping, ensuring that the tool remains stable during high-speed rotation and load changes.

5. High durability:

Made of high-quality alloy steel or special materials, hardened and precision ground to ensure good performance after long-term use.

6. Customization options:

Some collet chucks can be customized according to customers' specific application requirements, such as special clamping range, non-standard interface design, etc.

Contact: Annie Fu

WhatsApp: +8618819762043

Email: annie@veyertool.com

Add: Room2121,Office Building 5A,Mingfa Commercial Plaza,Changsha City,CHINA.