During the drilling process, due to the action of cutting force, small protrusions or burrs are formed on the surface of the workpiece or the edge of the hole. These burrs may appear as irregular small protrusions, usually smaller and possibly below 0.2mm. In actual processing, these burrs may affect subsequent assembly and performance, so hole deburring treatment is often necessary. So how should we mechanically remove these small burrs and difficult to handle workpiece surfaces?

Introduce two deburring tools for drilled holes suitable for narrow surfaces:

Suitable for hole burr removal, polishing, tool marks, etc. from metal parts' inner holes, cross holes, openings, edges, and narrow workpieces.

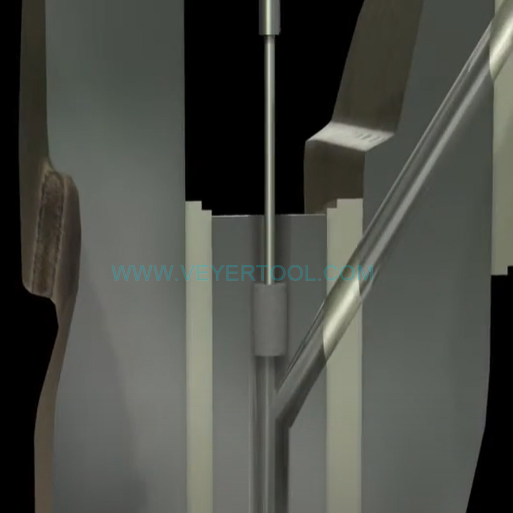

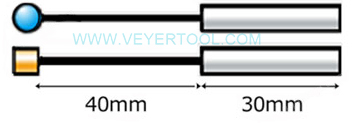

1.Ball Shaped Oil Stone Grinding Head

2.Cylindrical Oil Stone Grinding Head

VEYER's deburring tools for drilled holes are both made of fiber oilstone material, and the entire surface of the head has grinding force. As long as the top of the head contacts the processing area, it can effectively hole deburring on the grinding surface. Suitable for equipment such as cnc machining centers, combination lathes, robots, specialized machine tools, drilling machines, and electronic grinding tools.

The material of the shaft is spring steel, which makes the contact with the workpiece softer and can effectively prevent surface unevenness during processing.

For more deburring tools, kindly contact VEYER directly !

Deburring Polishing Finishing Brushes:

Surface deburring finishing tools: Surface Ceramic Fiber Brush,Extra Large Surface Ceramic Fiber Brush, End Type Ceramic Fiber Brush...//Stainless Steel Wire Brush...

Cross internal holes tools : Internal Cross Holes Ceramic Fiber Brush, Flex Ball Hone,Micro Holes Ceramic Fiber Brush...

Micro mini tools: Micro Holes Ceramic Fiber Brush// Ceramic Deburring Brush

Back or side burrs tools: Flexible Oil Stone Grinding Rod

Threads tools: Side Wheel Brush, Pipe Hole Brush...

Application:

Automated Deburring, Crosshole Deburring & Finishing, Detailed Finishing, Manual Deburring, Surface Deburring & Finishing, Metal cleaning,Mold polishing...

Widely used in CNC Machining Centers, Combined Lathes, Robotics Hand, Special machines,Bench Machine, End Milling Drilling Machine, Full Automatic Deburring Station, Aotumatic Production Line or Some used with Hand Electric Drill...

Industry:

3C Electronic Metal Parts, Mechanical Accessories, Precision Hardware Parts, Automobile Powertrain Motor Cylinders Head, Aerospace,New Energy, Medical Healthy, Robotics...

Contact: Annie Fu

WhatsApp: +8618819762043

Email: annie@veyertool.com

Add: Room2121,Office Building 5A,Mingfa Commercial Plaza,Changsha City,CHINA.